Do you remember last time we compared Wood molding and PU molding? What! You haven’t read that before! Go to check it out!

This time, let’s talk about the differences between two mainline mouldings of PS and PU mouldings. In the decoration materials, the mainline mouldings are the things that we can touch and see. When we are choosing the decoration materials, it is easy for us to decide the doors and cabinets that we like.

Have you ever thought about where do these mouldings which on the doors or cabinets come from? The craftsman needs to nail the mouldings on the doors first and then paints them. We are going to introduce the advantages and weaknesses of the two mainline mouldings-PS and PU.

Are PS and PU the same mouldings?

Many people have the same question as you. And they said the PS and PU mouldings are all made of plastic. They can’t find the differences. Actually, these two mainline mouldings have big differences!

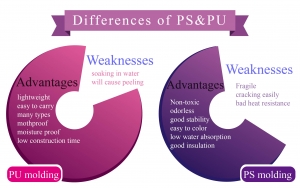

The features of PS and PU mainline mouldings

-

PS mainline moulding

- Advantages: Non-toxic, odorless, good insulation, easy to color, low water absorption, and good stability.

- Weaknesses: Fragile, reduced impact strength, cracking easily, and bad heat resistance.

-

PU mainline moulding

- Advantages: lightweight, easy to carry, low construction time, many types, moisture proof, and mothproof.

- Weaknesses: Long-term soaking in water will cause peeling, erosion, and other hydrolysis phenomena.

-

Use conditions

- PS moulding has good water resistance. It can use in the humid environment, such as the bathroom. On the other hand, it will become deformation, soften, and melt because of high heat. The use conditions are limited.

- PU moulding is not only lightweight but also easy to install on the high area. Paint the anti-UV paint on the surface of PU moulding, it can use in outdoor. It is also easy to maintain and clean. Just use a cloth to clean the dust.

-

Environmental protection

- PS moulding can’t be natural decomposition. It will release carcinogenic substances in high heat. Don’t use in high heat environment.

- PU moulding can be natural decomposition based on didn’t do the process on the surface. It needs 70 years to decompose and melt in the soil.

After reading this article, you are getting to know these two mainline mouldings of PS and PU. Depends on your request and space to choose the best mainline moulding to decorate your places.

Contact info: customer.en@goodware.com.tw