No longer afraid that the PU decorative products will be damaged, DIY repairing is super simple.

We have already introduced a lot of PU decorative products. These products will inevitably be paint stripping, small scratches and even damage due to collision and friction in daily life. How to fix this situation? The next things is that we will introduce the repair process of PU products in detail. Therefore, we can repair all kinds of products at home by DIY.

1.The preparation of material sand tools

|

Repair material |

Plastic soil: AB glue, water-based pourable silicone |

|

Surface repairing material |

Putty ash, latex paint, paint, varnish |

|

Surface cleaning tools |

Brush, Air compressor |

|

Other tools |

Utility knife, spatula |

2.Concave pits repair

Sometimes, the PU decorative products will cause dents due to collisions when you use them. What is more, some behaviors may lead serious concave pits. In this situation, we can use a pu material which called fill soil to repair it.

There are many types of fill soil such as car replenishment soil for car touch up surface, AB replenishment soil (epoxy replenishment soil), toothpaste replenishment soil (plastic replenishment soil) and so on.

The commonly filling soil we used is plastic filling. Moreover, toothpaste packaging is very convenient to use. Furthermore, our filling soil belongs to PU decorative products, so it is safe for us to use it. After filling the pits, we need to use the back of utility knife to clear the excess soil.

3. Crack filling

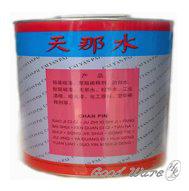

If the cracks on PU decorative products are appeared, we can fill the cracks with AB glue or water-based silicone which is the pourable silicone. After filling the cracks, the next step is wiping off the excess glue with a damp cloth. (If you use AB glue, you need to use a rag with the Tiannal water [banana water] ) Please be careful about the Tiannal water which is not the pu material, and it is slightly toxic.

4. Surface repair for PU decorative products

4. Surface repair for PU decorative products

The surface of PU decorative products repairing can begin after the soil hardening. Generally, we directly use the pu material which called putty ash for surface treatment, because any small traces can be filled with the putty ash.

5. Surface Polishing

After the putty ash has dried out, we can use sandpaper to polish and repair the surface of PU decorative products. From number 150, followed with number 280 /400/500/600 sandpaper, which can achieve the best texture. (It can just be polished to number 400.)

After sanding, we can clean the surface with a brush or air gun to remove fine particles such as dust, which is good for painting.

6. Painting for PU decorative products

The first layer of paint is generally made of latex paint or water-based primer. After this layer of paint drying, we can apply the paint with the target color which is similar with the original color of the product. After that paint is dried, the last layer of varnish is painted.

Note

1. If the dent on the surface of the PU decorative products is not deep, you can start directly from the surface repair of step III.

2. Tianna Water (banana water) is slightly toxic. Please use it carefully in accordance with the toxic chemicals operating procedures.

The above is the DIY repair process for PU decorative products. Have you got it? If you want more information, please click here