After home decoration, you may worry about the persistence of PU moulding. If the cracks show up at the junction of PU moulding, how to repair? You might also wonder what reasons cause the cracks. Don’t worry. Goodware is going to tell you the reasons and solutions!

Reasons and Solutions

-

Jerry-built

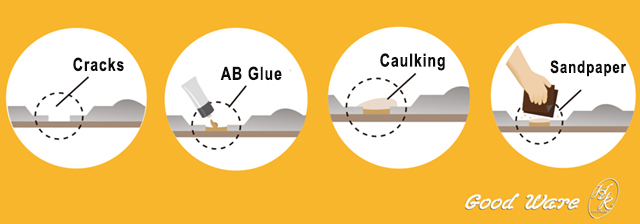

In order to request the fast efficiency, the construction unit often omits the correct construction method, such as the caulking process. In general, the correct construction method is to paint a layer of AB glue at the junction first, then, do the caulking process. Finally, use the sandpaper to make the surface smooth. But some construction units will omit the AG glue process. That’s why the cracks will show up easily.

-

Thermal expansion and contraction

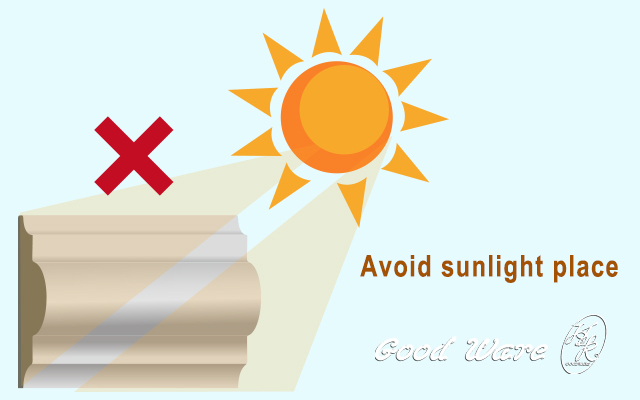

If the density of PU moulding is insufficient, it may cause the expansion and contraction. The cracks will cause broken and influence the beauty of the interior. You should choose high-quality PU moulding to decorate your house, such as Goodware PU decorative materials. Besides, you also need to notice the installation place, avoid the big temperature difference place and sunlight exposure place.

-

Proportion of paint and water

If you don’t notice the proportion of paint and water, the junction and surface of PU moulding will cause the cracks after painting. Remember the proportion of paint and water is 1:2. If the water is too much, the bottom of PU moulding will become moldy and cracked.

As a result, these are the reasons and solutions. Goodware has 30-year experiences in production PU decorative materials. We insist high quality and great service. That’s why a proverb goes “You need good tools to master a job”. Come to check out our products!

Contact info: customer.en@goodware.com.tw

※ Copyright for all GoodWare, reproduced indicate the source